| Research Programs |

|

|

|

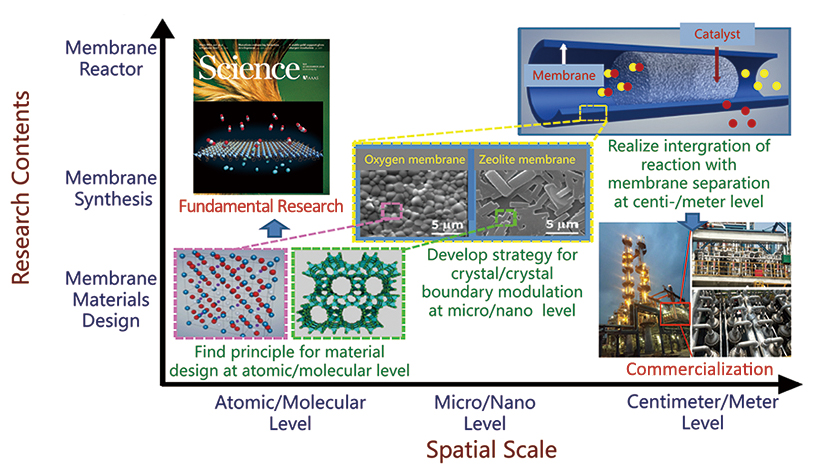

This figure shows the research route map of the Yang group. We design membrane materials with ideal crystalline structure and chemical composition at atomic/molecular level, and develop strategies to control the growth of crystals and crystal boundaries at the micro/nano level for the synthesis of high-performance membranes. We construct membrane reactors to integrate reaction and separation for process intensification at the centimeter/meter level. Our target is to design high-performance membranes for important separation processes, disclose the science behind membrane and catalysis, develop membrane related technologies and commercialize membrane technologies for new separation and reaction-separation processes in industries.

Mixing Conducting Membranes

|

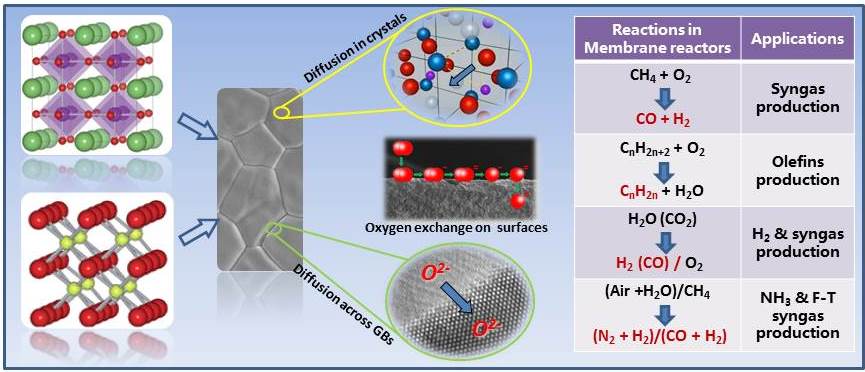

Mixed ionic-electronic conducting (MIEC) materials with crystal structures of perovskite (ABO3, top left) and fluorite (MO2, bottom left) can be used as membranes for oxygen or hydrogen separation, electrodes of solid oxide cells for energy conversion. The key of these materials is the oxygen ionic transport in lattice (top middle), across the grain boundaries (bottom middle) as well as oxygen exchange on gas-solid interfaces (center). We develop materials according to requirements of catalytic reactions in membrane reactors (right), and construct permeation models to deep understand the bulk and interface kinetics of the electrochemical processes, as well as the science of reaction-separation coupling in the solid oxide devices. The Yang group is developing the science and technologies related to MIEC materials as membrane separators, membrane reactors and catalysts for gas purification, process intensification, and cells and batteries. The research activities involve new materials development, design of membrane reactors for new catalytic reaction-separation coupling, conversion of small and stable molecules in catalytic membrane reactors, development of models to disclose the permeation and reaction kinetics in membrane separators and reactors, as well as various techniques related to the practical application of the membrane processes. In recent years, we proposed a new principle for the design of dual-phase MIEC membranes leading to a significant increase of permeability, built an universally applicable kinetic permeation model with clear parameter meanings for the description of oxygen permeation process. We disclosed the degradation mechanism of membranes at low temperatures and developed simple and widely applicable methods to stabilize the permeation at low temperatures.

Research topics:

Materials development for O2、H2、CO2 separation Composition and microstructure design of membrane materials Permeation mechanism development Membrane preparation technology and membrane modules development

Further reading:

The current status of high temperature electrochemistry-based CO2 transport membranes and reactors for direct CO2 capture and conversion, P. Zhang, J. Tong, K. Huang, X. Zhu, W. Yang, Prog. Energy Combust. Sci., 2021, 82, 100888. Full Article Link Universally applicable kinetic model for mixed ionic-electronic conducting membranes, Y. Zhu, W. Li, L. Cai, X. Zhu, W. Yang, Chem. Eng. Sci., 2020, 215, 115455. Full Article Link Microstructural and interfacial designs of oxygen–permeable membranes for oxygen separation and reaction–separation coupling, X.Zhu, W. Yang, Adv. Mater., 2019, 31, 1902547. Full Article Link H2S-tolerant oxygen-permeable ceramic membranes for hydrogen separation with a performance comparable to those of palladium-based membranes, W. Li, Z. Cao, L. Cai, L. Zhang, X. Zhu, W. Yang, Energy Environ.Sci.,2017, 10, 101-106.Full Article Link Nanoparticles at grain boundaries inhibit the phase transformation of perovskite membrane, Y. Liu, X. Zhu, M. Li, R. P. O’Hayre, W. Yang, Nano Lett.,2015, 15, 7678-7683. Full Article Link

Molecular Sieving Membranes

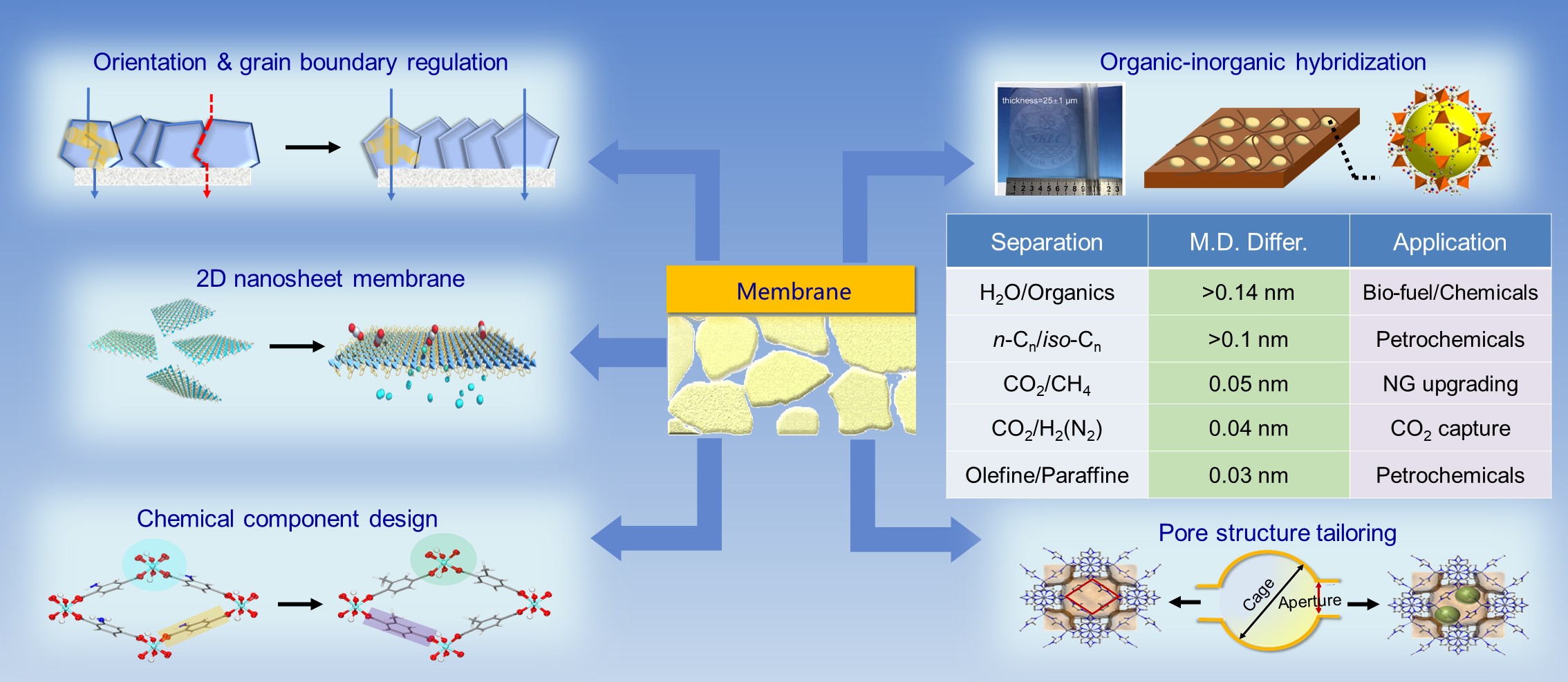

Yang Group has been devoting to synthesis and application of high performance molecular sieve membranes, exemplified with metal-organic framework membranes, seeking for an alternative energy-efficient and environment-friendly separation solution towards organics refinery, petrochemical separation, CH4 upgrading and CO2 capture, etc. We rationally design materials with chemical diversities and pore structures, manipulate micro-architectures of membranes with ideal orientation and grain boundaries, optimize transport properties by organic-inorganic hybridization, and further minimize the mass-transfer resistance by 2D nanosheet concept.

Research topics:

Pure molecular sieve membranes Organic-inorganic hybrid membranes 2D ultrathin nanosheet membranes Novel membrane separation and adsorption

Further reading:

Tuning of Delicate Host–Guest Interactions in Hydrated MIL-53 and Functional Variants for Furfural Capture from Aqueous Solution, N. Cao, H. Wang, Y. Ban, W. Yang, et al., Angew. Chem. Int. Ed. 2021, 60, 1629-1634. Full Article Link ZIF-L membrane with a membrane-interlocked-support composite architecture for H2/CO2 separation, K. Yang, Y. Ban, W. Yang, et al., Science Bulletin 2021, doi: 10.1016/j.scib.2021.05.006. Full Article Link Microstructural Engineering and Architectural Design of Metal-Organic Framework Membranes, Y. Liu, Y. J. Ban, W. S. Yang, Adv. Mater.,2017, 29, 1606949. Full Article Link Two-Dimensional Metal-Organic Framework Nanosheets for Membrane-Based Gas Separation, Y. Peng, Y. S. Li, Y. J. Ban, W. S. Yang, Angew. Chem. Int. Ed.,2017, 33, 9757–9761. Full Article Link Confinement of Ionic Liquids in Nanocages: Tailoring the Molecular Sieving Properties of ZIF-8 for Membrane-Based CO2 Capture, Y. J. Ban, Z. J. Li, Y. S. Li, Y. Peng, H. Jin, W. M. Jiao, A. Guo, P. Wang, Q. Y. Yang, C. L. Zhong, W. S. Yang, Angew. Chem. Int. Ed.,2015, 54, 15483–15487. Full Article Link Metal-Organic Framework Nanosheets as Building Blocks for Molecular Sieving Membranes, Y. Peng, Y. S. Li, Y. J. Ban, H. Jin, W. M. Jiao, X. L. Liu, W. S. Yang, Science, 2014, 346, 1356–1359.Full Article Link

Membrane Reactor

|

Reaction and separation can be integrated in a membrane reactor with great energy saving and process simplification. In the membrane reactor, one of the products can be in-situ selectively removed or one of reactant can be input through membranes, which can shift the reaction balance to the generation of target products, eliminate undesired side reactions as well as realize the separation of target products. The research activities in our research group involve application-oriented design of membrane materials, establishment of membrane reactors, development of models to comprehend the synergetic functions of reaction and separation, and catalytic materials development for membrane reactors. Recently, we proposed a new catalytic membrane reactor to fulfill a nine-step industrial process in one-step saving > 60% more than conventional processes, a new concept of efficient hydrogen separation using oxygen-permeable membranes and coupled the membrane reactors with pre-combustion CO2 capture, reducing the CO2 capture energy consumption by 59%. Now, new membrane reactors are under developing for the conversion of stable small molecules or biomass-derived platform chemicals to value-added chemicals and fuels.

Research topics:

Mixing conducting membrane reactors MOF and MOF-based membrane reactors Zeolite membrane reactors Electrocatalytic membrane reactors Kinetics of reaction-separation coupling

Further reading:

High-performance oxygen transport membrane reactors integrated with IGCC for carbon capture, L. Cai, X. Wu, X. Zhu, A. F. Ghoniem, W Yang, AIChE J.,2020, 66 e16247. Full Article Link

Dual-phase membrane reactor for hydrogen separation with high tolerance to CO2 and H2S impurities, L. Cai, S. Hu, Z. Cao, H. Li, X. Zhu, W. Yang, AIChE J., 2019, 65, 1088-1096. Full Article Link H2S-tolerant oxygen-permeable ceramic membranes for hydrogen separation with a performance comparable to those of palladium-based membranes, W. Li, Z. Cao, L. Cai, L. Zhang, X. Zhu, W. Yang, Energy Environ.Sci.,2017,10,101-106.Full Article Link Conversion of xylose into furfural in a MOF-based mixed matrix membrane reactor, H. Jin, X. Liu, Y. Ban, Y. Peng, W. Jiao, P. Wang, A. Guo, Y. Li, W. Yang, Chem. Eng. J., 2016, 305, 12-18. Full Article Link Integration of nine steps for producing ammonia and liquid-fuel synthesis gases in one membrane reactor, W. Li, X. Zhu, S. Chen, W. Yang, Angew. Chem. Int. Ed.,2016, 55, 8566-8570. Full Article Link

Zn-based batteries

|

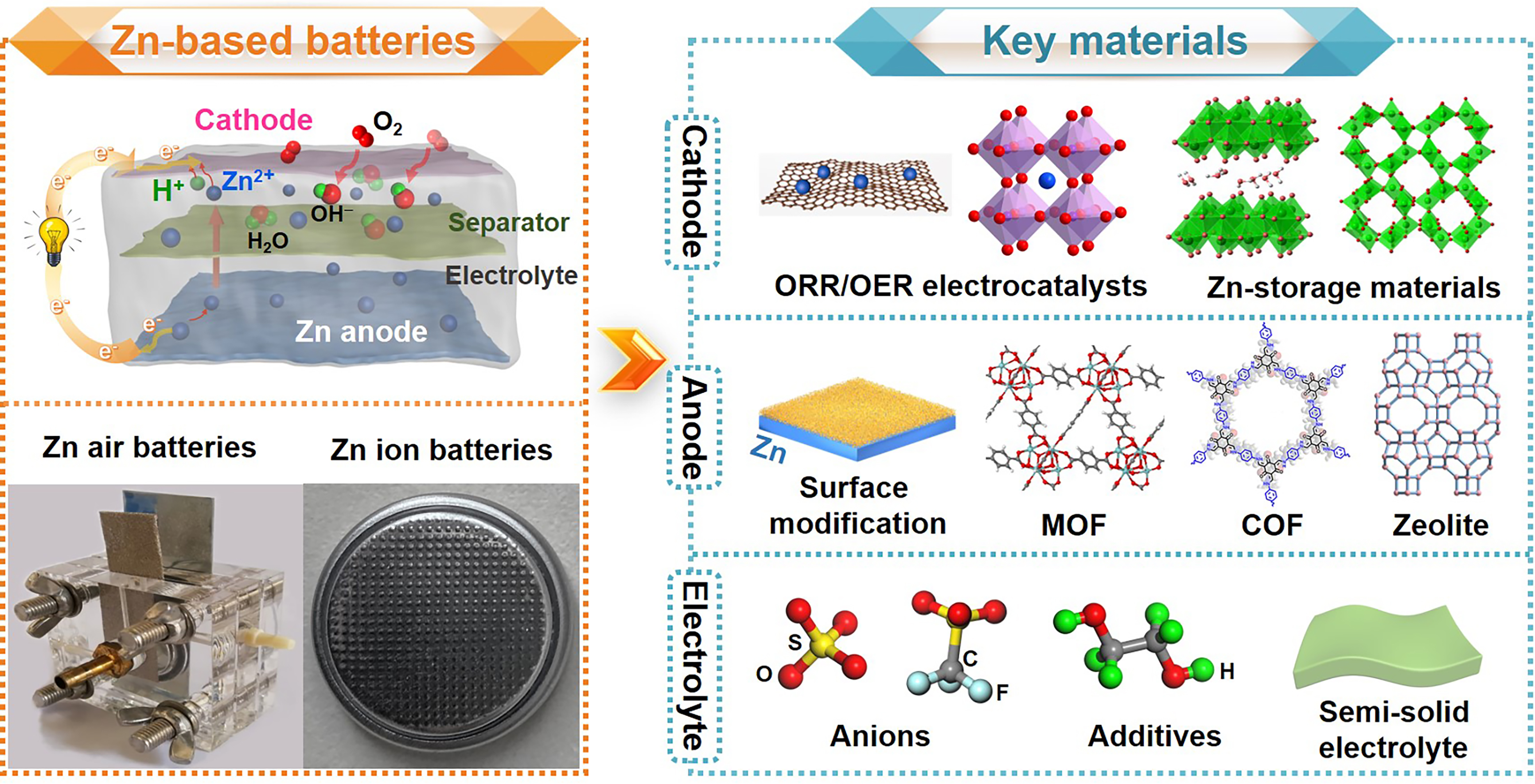

A battery is a device that stores chemical energy and converts it to electrical energy. State-of-the-art lithium-ion batteries face cost and safety concerns due to the scarcity of lithium sources and utilization of the flammable organic electrolyte. Aqueous Zn-based batteries, such as Zn air batteries (ZABs) and Zn ion batteries (ZIBs), are a natural replacement because of their outstanding merits in safety, cost, and environmental impact. However, aqueous Zn-based batteries are still in their infancy and there are still some challenges, limiting their practical application. Our group focuses on developing suitable cathodes and anodes, and designing the electrolytes, together with understanding their energy storage mechanism. Our final goal is to make batteries with high energy density, high safety, long cycle life and low cost. For aqueous ZABs, our group has firstly determined the active center for oxygen evolution reaction (OER) and achieved a better understanding on the materials characteristics (such as oxygen vacancy, layered structure) that affect OER activity, thus giving guidance for designing high-performance electrocatalysts for the OER. Finally, the excellent OER performance and low cost of NiFe hydroxide make it a strong candidate electrocatalyst for commercial ZABs. For aqueous ZIBs, our group provided direct and compelling evidence to demonstrate the synergistic H+/Zn2+ dual ion insertion mechanism at the cathode and unveil the reason for the instability of V-based cathode materials in aqueous electrolyte. Based on such understanding, novel methods such as in situ high-voltage activation and metal-ion pre-insertion into the layer gallery were adopted, showing significant enhancement of the capacity and the stability of the cathode. The cathode developed in our group holds a strong position as a candidate for future commercial Zn-based batteries, while the fundamental insights unveiled from our studies also deepen the understanding of aqueous Zn-based batteries and lay a solid foundation for future discovery of new and better cathodes.

Research topics:

Zn air batteries Zn ion batteries Electrocatalysis

Further reading:

Understanding the dissolution and phase transformation mechanisms in aqueous Zn/α-V2O5 batteries, K. Zhu, T. Wu, K. Huang, Chem. Mater.,2021, 33, 4089-4098. Full Article Link A high-voltage activated high-performance cathode for aqueous Zn-ion batteries, K. Zhu, T. Wu, K. Huang, Energy Storage Mater.,2021, 38, 473-481. Full Article Link Reversible molecular and ionic storage mechanisms in high-performance Zn0.1V2O5·nH2O xerogel cathode for aqueous Zn-ion batteries, K. Zhu, T. Wu, W. van den Bergh, M. Stefik, K. Huang, ACS Nano,2021, 15, 10678-10688. Full Article Link Synergistic H+/Zn2+ dual ion insertion mechanism in high-capacity and ultra-stable hydrated VO2 cathode for aqueous Zn-ion batteries, K. Zhu, T. Wu, S. Sun, W. van den Bergh, M. Stefik, K. Huang, Energy Storage Mater.,2020, 29, 60-70. Full Article Link The roles of oxygen vacancies in electrocatalytic oxygen evolution reaction, K. Zhu, F. Shi, X. Zhu, W. Yang, Nano Energy,2020, 73, 104761. Full Article Link NaCa0.6V6O16·3H2O as an ultra‐stable cathode for Zn-ion batteries: the roles of pre-inserted dual-cations and structural water in V3O8 layer, K. Zhu, T. Wu, K. Huang, Adv. Energy Mater.,2019, 9, 1901968. Full Article Link Application of in situ techniques for the characterization of NiFe-based oxygen evolution reaction (OER) electrocatalysts, K. Zhu, X. Zhu, W. Yang, Angew. Chem. Int. Ed.,2019, 58, 1252-1265. Full Article Link A high capacity bilayer cathode for aqueous Zn-ion batteries, K. Zhu, T. Wu, K. Huang, ACS Nano,2019, 13, 14447-14458. Full Article Link Layered Fe-substituted LiNiO2 electrocatalysts for high-efficiency oxygen evolution reaction, K. Zhu, T. Wu, Y. Zhu, X. Li, M. Li, R. Lu, J. Wang, X. Zhu, W. Yang, ACS Energy Lett.,2017, 2, 1654-1660. Full Article Link Perovskites decorated with oxygen vacancies and Fe-Ni alloy nanoparticles as high-efficiency electrocatalysts for the oxygen evolution reaction, K. Zhu, T. Wu, M. Li, R. Lu, X. Zhu, W. Yang, J. Mater. Chem. A,2017, 5, 19836-19845. Full Article Link Atomic-scale topochemical preparation of crystalline Fe3+-doped β-Ni(OH)2 for an ultrahigh-rate oxygen evolution reaction, K. Zhu, H. Liu, M. Li, X. Li, J. Wang, X. Zhu, W. Yang, J. Mater. Chem. A,2017, 5, 7753-7758. Full Article Link

Zeolite Membrane Commercialization

|

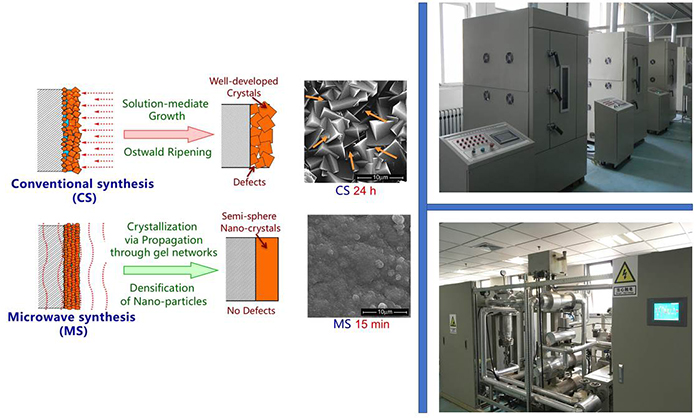

Zeolites are microporous aluminosilicates composed of tetrahedra linked together at the corners to form a highly regular three-dimensional network. Zeolites are ideal membrane materials due to their extraordinary thermal, mechanical and chemical stability. Zeolite membranes have been extensively studied ever since 1989. It has been demonstrated that the separation performance of zeolite membranes was influenced by not only their framework topologies, but also multiple microstructural factors such as membrane thickness, Si/Al ratio, preferred orientation and grain boundary. Several methods and techniques (like microwave heating) have been developed and proven quite effective for a more precise control over their microstructures. The Yang group are one of the first research groups exploring microwave heating synthesis of zeolite membranes. A novel“in situ aging-microwave heating” method was developed for the synthesis of NaA membrane. After in-situ aging, a gel layer is first formed on the support which contains plenty of pre-nuclei. During the following microwave assistant crystallization, these pre-nuclei rapidly and simultaneously develop into crystal nuclei, and then grow into a compact A-type zeolite membrane. This method could be further extended to other types of zeolite membranes, i.e., FAU-type, T-type. Of particular note, microwave-assisted technique has been successfully used for large-scale production of LTA membranes (Top right), and the microwave-synthesized zeolite membrane unit can be used for dewatering of organics through pervaporation or vapor permeation (Bottom right).

Research topics:

Microwave synthesis of zeolite membranes (LTA, FAU, T…) Dewatering of organics (alcohols, Ethers, Ketones, Esters…) through pervaporation or vapor permeation Scaling up synthesis and application processes of zeolite membranes

Further reading:

In situ electrochemical synthesis of oriented and defect-free AEL molecular-sieve films using ionic liquids, T. W. Yu, W. L. Chu, R. Cai, Y. C. Liu, W. S. Yang, Angew. Chem. Int. Ed., 2015, 54, 13032-13035. Full Article Link Fabrication of highly b-oriented MFI film with molecular sieving properties by controlled in-plane secondary growth, Y. Liu, Y. Li, W. Yang, J. Am. Chem. Soc., 2010, 132, 1768–1769. Full Article Link Microwave synthesis of high performance FAU-type zeolite membranes: Optimization, characterization and pervaporation dehydration of alcohols, G. Q. Zhu, Y. S. Li, H. Zhou, J. Liu, W. S. Yang, J. Membrane Sci., 2009, 337, 47-54. Full Article Link Hydrothermal stability of LTA zeolite membranes in pervaporation, Y. S. Li, H. Zhou, G. Q. Zhu, J. Liu, W. S. Yang, J. Membrane Sci., 2007, 297, 10-15. Full Article Link Synthesis of a high-permeance NaA zeolite membrane by microwave heating, X. C. Xu, W. S. Yang, J. Liu, L. W. Lin, Adv. Mater., 2000, 12, 195-198. Full Article Link

Catalytic Conversion of Light alkanes

|

The left picture illustrates the structure of Mo-V-based mixed metal oxides with hexagonal and heptagonal channels, which are formed by the building unit assembly of polyoxomolybdates under hydrothermal conditions. And the particular channel structure can adsorb and activate small molecules (such as ethane and propane), and transform them into high-value chemicals. Of particular note, large-scale production of Mo-V-based mixed metal oxides has been successfully developed by hydrothermal technique (Top right), and the ring-shaped catalysts have been successfully used for pilot test of propane oxidation to acrylic acid (Bottom right). The fossil feedstock in recent years is shifting towards light alkanes (C2~C4) due to the abundant resources, lower prices and negligible environment impact. The conversion of light feedstocks to high-value chemicals (polymers, paints, lubricants etc.) through highly-selective catalysts in the presence of oxygen is an increasing important topic. At present, the most promising catalysts are mixed metal oxides,VPO catalyst and heteropoly compounds due to their outstanding performance under favorable reaction conditions. MoVTeNbO mixed metal oxide with excellent activity and selectivity has been successfully developed in our group for propane oxidation to acrylic acid. The large-scale synthesis of catalysts and demonstration plant for 1000 t/a production of acrylic acid are in progress. New catalytic materials are also being investigated for their properties and applications in selective oxidation of light alkane.

Research topics:

Oxidative dehydrogenation of light alkanes Selective (amm) oxidation of light alkanes Oxidative removal of CO in effluent from the selective oxidation of light alkanes

Further reading:

Synergistic effects of phases in the selective oxidation of isobutane over the supported (NH4)3HPMo11VO40 catalysts,Xue Cai*, Yue Ma, Qi Zhou, Zitong Zhang, Wenling Chu*, Weishen Yang,Reaction Kinetics, Mechanism and Catalysis, 2021,133:293-308. Full Article Link Selective Removal of CO in Hydrocarbons-Rich Industrial Off-gases over CuO-CexZr1-xO2 catalysts, Xue Cai*, Qi Zhou, Yue Ma, Li Jiang, Wenwen Yu, Wenling Chu*, Rui Cai, Weishen Yang, Catalysis Surveys from Asia, 2021, 25: 68-71. Full Article Link Selective removal of CO from hydrocarbon-rich industrial off-gases over CeO2-supported metal oxides, Wenwen Yu, Qi Zhou, Hongkui Wang, Yanchun Liu, Wenling Chu*, Rui Cai*, Weishen Yang, J. Mater. Sci., 2020, 55, 2321-2332. Full Article Link Polyoxometalate catalysts with co-substituted VO2+ and transition metals and their catalytic performance for the oxidation of isobutane, Yanchun Liu, Jinggang He, Wenling Chu*,Weishen Yang*, Catal. Sci. & Technology, 2018, 8, 5774-5781. Full Article Link Highly efficient removal of CO in effluent streams from real-life propane oxidation process over CuO-CeO2-based catalysts, Wenling Chu*, Yanchun Liu, Hongkui Wang, Weishen Yang*, ChemCatChem., 2018, 10, 4292-4299. Full Article Link Effect of V-containing precursors on the structure and catalytic performance of Cs-substituted phosphomolybdates for isobutane oxidation, Jingfang He, Yanchun Liu, Wening Chu*, Weishen Yang*, Appl. Catal. Gen., 2018, 556:104-112. Full Article Link

|

|

|

|

|

|

|