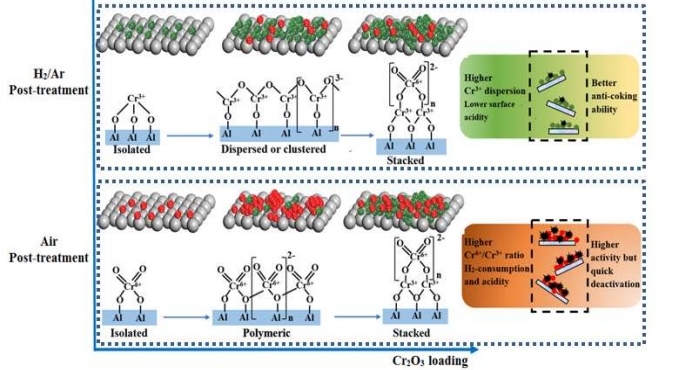

Our group prepared the Cr2O3/Al2O3 catalysts with various loadings and calcination processes, and investigated their cataltyic performance in dehydrogenation of propane (PDH). It was found that the Cr2O3/Al2O3 catalysts by post-treatment of air calcination achieved the higher propane conversion than their counterparts calcined by H2/Ar, while the latter exhibited a better anti-coking ability and then the higher resistance against deactivation. Moreover, many characteristic investigations showed that the Cr2O3/Al2O3 catalysts calcined in air exhibited the higher Cr6+/Cr3+ ratio, a larger amount of H2 consumption and concentration of surface acid sites. On the contrary, the post-treatment by H2/Ar effectively prevented the polymerization of the monomeric and/or oligomeric chromate species by the reduction of Cr6+ species, and the non-redox surface Cr3+ clusters or microcrystalline with well dispersion are the dominant species for all the Cr2O3/Al2O3-H2/Ar catalysts. This work has been published in Industrial & Engineering Chemistry Research.

The article links:https://doi.org/10.1021/acs.iecr.2c03031